Fabric Storage Box Manufacturer & Wholesale Supplier

We are a professional manufacturer and wholesale supplier of fabric storage boxes, specializing in bulk production and OEM/ODM customization. With years of factory experience, we provide reliable and cost-effective storage solutions for global wholesalers, retailers, supermarkets, hotels, and e-commerce brands. Our storage boxes are designed to be durable, collapsible, and easy to transport, making them a practical choice for businesses that require consistent quality and timely delivery.

Our fabric storage boxes are versatile organizers crafted from high-quality fabrics including non-woven, Oxford, linen, and cotton blends. Designed to store clothes, toys, bedding, and other household items, they help maintain a neat and organized space while offering durability for long-term use. The foldable construction makes the boxes lightweight and space-saving, which not only improves convenience for end users but also reduces logistics and warehousing costs for wholesale buyers. Reinforced stitching and sturdy panels provide structural stability, ensuring the boxes remain reliable in everyday applications.

As one of the trusted fabric storage boxes suppliers & manufacturers, we support OEM/ODM customization in size, fabric, color, and branding. This allows our partners to develop tailored products that enhance their competitiveness across retail and online channels.

- Fabric Storage Boxes & Bins

- Drawer organizers

- Storage bags

- hanging closet organizers

- Foldable fabric storage box

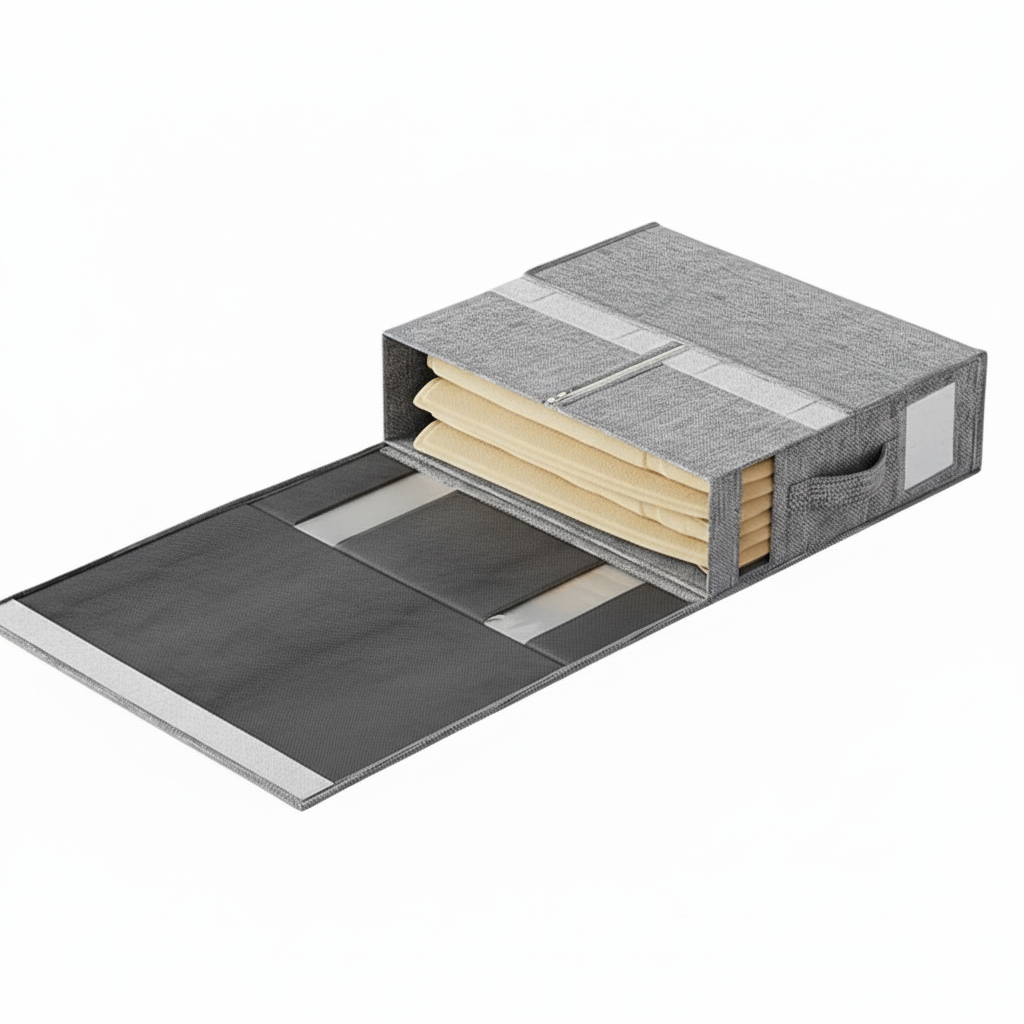

- Large-capacity/under-bed storage box

- fabric covered storage boxes with lids

- Underwear storage box

-

Heavy-Duty Oxford Fabric Storage Bags with Reinforced Handles

Learn More -

Cotton Rope Bear Laundry Hamper & Toy Storage Basket for Bedroom

Learn More -

Portable Square Non Woven Storage Box for storaging Toy

Learn More -

Customized non-woven linen trapezoidal storage box

Learn More -

PP Plastic Storage Organizer Zipper Box

Learn More -

Classic Collapsible Fabric Storage Bins

Learn More -

Customized multi-compartment storage boxes

Learn More -

Customized fabric storage box with window

Learn More -

Shark Shape Fabric Storage Basket

Learn More -

Customized cotton and linen storage baskets

Learn More -

Customizable bed sheet storage box

Learn More -

Customizable handle storage box

Learn More -

Customized felt storage box

Learn More -

Foldable pop-up laundry basket

Learn More -

Reinforced-Handle Storage Cubes

Learn More -

Customized cotton rope storage basket

Learn More -

Stackable Steel-Frame Clothes Storage Organizer Bag

Learn More -

Washable leather bag storage box

Learn More -

Customized old clothes storage boxes

Learn More

DON’T FIND THE PRODUCT YOU NEED ON THE WEBSITE?

Contact us, and we will send you a catalog of 8,000 storage products!

Partnering with us as your fabric storage box supplier means gaining access to a factory that prioritizes quality, customization, and large-scale supply. We offer competitive wholesale pricing, strong production capacity, and strict quality control to ensure every shipment meets international standards. Our export experience allows us to support supermarkets, e-commerce sellers, and wholesale distributors worldwide with timely delivery and professional service. By choosing us, you benefit from a trusted manufacturing partner committed to helping your business grow in the global storage solutions market.

Home and bedroom organization – ideal for storing clothes, toys, blankets, and daily essentials

Closet and wardrobe systems – keeping drawers and shelves tidy and space-efficient

Office and retail spaces – perfect for organizing documents, supplies, or product displays

Hotels and apartments – providing elegant and practical storage for guests

E-commerce and wholesalers – supporting OEM/ODM customization for brand collections

Fabric storage boxes are widely used across residential, commercial, and hospitality environments, offering aesthetic appeal, functionality, and foldable convenience.

Household storage materials and application technology

Material: Fabric - non-woven fabric, Oxford cloth, linen, etc. Board - cardboard, density board, hollow board, PP board, etc.

Weaving, Sewing Process

For some fabric storage products, such as storage boxes, storage bags, etc., weaving technology is often used. The fiber material is made into storage products by weaving, sewing, etc. The weaving process can create different textures and patterns, making the product more beautiful, and also has a certain softness and breathability.

Folding Process

Some foldable storage products will use folding technology. By designing a special structure, the product can be easily folded up to save space. This process is common in products such as folding storage boxes and folding hangers, which are convenient to carry and store.

Related Industry Applications

If you want perfect home storage choose Wenzhou Tianze

Consult now to start your personalized storage journey

Subscription

Subscription

Frequently Asked Questions

-

What materials are fabric storage boxes made from?

>Fabric storage boxes are typically made from non-woven fabrics, Oxford cloth, cotton, or linen blends, each offering different benefits. Non-woven fabric is lightweight and affordable, making it popular for mass-market and promotional products. Oxford cloth provides a stronger, more durable option, often with moisture-resistant properties. Linen and cotton blends are favored in premium markets for their natural look, breathability, and eco-friendly appeal. To maintain structure, the fabric is reinforced with sturdy cardboard or plastic panels, ensuring the box keeps its shape even when loaded with clothing, bedding, or toys. For wholesale buyers, the choice of material can be tailored to local market needs, balancing cost, durability, and aesthetics. OEM/ODM customization allows partners to select fabrics that align with their branding and target customer preferences.

-

What is the standard configuration of a fabric storage box?

>Most fabric storage boxes are designed with a collapsible structure, which allows them to be shipped and stored flat, saving valuable space and reducing logistics costs. When in use, the box can be quickly assembled with reinforced panels that provide stability and support. Standard configurations often include handles for easy carrying, lids for dust protection, and zippers or Velcro closures depending on the design. Some models feature transparent windows so users can identify contents without opening the box, which is especially useful for clothing and seasonal storage. For wholesale and retail purposes, these configurations can be customized—buyers can request specific lid types, handle placements, or reinforced stitching to meet their market’s functional and aesthetic needs, ensuring products are both practical and appealing to end customers.

-

Why are fabric storage boxes foldable?

>The foldable design of fabric storage boxes is one of their most important features, offering clear advantages for both suppliers and end users. From a manufacturing and logistics perspective, foldability allows boxes to be flat-packed into cartons, maximizing container space and reducing transportation and warehousing costs. This makes them highly efficient for wholesale distribution and international shipping. For consumers, foldability means easy assembly when needed and compact storage when not in use, saving space in homes, hotels, and dormitories. Unlike rigid plastic or wooden boxes, fabric storage boxes provide flexibility without sacrificing durability. Reinforced panels and stitching keep the box stable when in use, but once folded, it can be neatly stored away. This dual benefit—cost savings for bulk buyers and convenience for end users—explains why foldability has become a global standard in fabric storage box design.

-

Are fabric storage boxes durable enough for bulk use?

>Yes. Fabric storage boxes are built with durable fabrics like Oxford or linen blends and reinforced with strong panels. Quality stitching ensures long-lasting performance even under frequent use. Unlike low-cost alternatives, wholesale-grade boxes are designed for repeated handling and heavy loads. Buyers can select thicker fabrics or reinforced designs for higher durability. These features make them suitable for retailers, supermarkets, and e-commerce sellers looking for reliable products for their customers.

-

What sizes are available for fabric storage boxes?

>Fabric storage boxes come in a wide range of sizes, from small organizers for socks and underwear to large boxes for quilts and bedding. Standard dimensions are often 30–60 cm, but custom sizes are available through OEM/ODM services. This flexibility allows wholesalers and retailers to offer varied product lines that meet diverse consumer needs. Buyers can also combine multiple sizes in one order to maximize market coverage and logistics efficiency.

-

Can I customize fabric storage boxes for my brand?

>Yes. OEM/ODM customization is one of the main advantages of fabric storage boxes. Buyers can select fabrics, colors, and sizes, and add logo printing, embroidery, or custom packaging to create branded products. Customization allows businesses to target specific markets with tailored designs, whether for premium retail, online shops, or promotional campaigns. With professional manufacturing support, fabric storage boxes can be adapted to fit any brand strategy or sales channel.

-

What is the typical MOQ (Minimum Order Quantity)?

>The standard MOQ for fabric storage boxes is usually 500–1,000 pieces per design. This quantity ensures efficient production and cost-effective shipping. For larger projects, higher volumes can reduce per-unit costs. Flexible solutions may be available for smaller trial orders or assorted sizes. Discussing specific requirements with the manufacturer helps determine the most suitable MOQ, balancing customization needs with competitive wholesale pricing and production efficiency.

-

What is the production process for fabric storage boxes?

>The process begins with fabric selection, cutting, and panel preparation. Reinforced materials are then stitched together with handles, lids, or zippers as required. After assembly, products undergo quality inspection before being flat-packed into cartons for shipping. For OEM/ODM orders, sampling and design approval come first to confirm details. This structured process ensures consistency, durability, and reliable lead times for wholesale buyers around the world.

-

How long does production take?

>Typical production lead time for fabric storage boxes is 25–35 days after sample approval and deposit. The exact time depends on order size, customization requirements, and fabric availability. For urgent orders, manufacturers can adjust schedules to meet deadlines. Large-scale production capacity helps ensure stable supply for wholesalers, supermarkets, and e-commerce brands, making it possible to deliver bulk orders on time without compromising quality standards.

-

How are fabric storage boxes packaged for shipment?

>Fabric storage boxes are usually flat-packed into export cartons, maximizing container capacity and reducing shipping costs. This packaging method also makes warehousing more efficient. For branded buyers, custom packaging options such as printed cartons or retail-ready boxes are available. Proper packing protects products during transit while ensuring easy assembly for end users. Bulk buyers benefit from lower freight costs and simplified inventory management.

-

What are the main applications of fabric storage boxes?

>Fabric storage boxes are widely used for organizing clothing, bedding, toys, and household items. They are also popular in hotels, dormitories, and commercial projects where compact and versatile storage is required. In retail, supermarkets and e-commerce sellers rely on them as cost-effective, high-demand products. Their foldable design and customizable features make them suitable for multiple sales channels, from large wholesalers to online marketplaces like Amazon and Walmart.

-

Which markets are fabric storage boxes most popular in?

>Fabric storage boxes are in strong demand across North America, Europe, and Asia, where home organization is a growing consumer trend. They are also expanding in emerging markets in the Middle East and South America. Buyers include wholesalers, supermarkets, retailers, and e-commerce platforms. With growing interest in eco-friendly and space-saving storage, demand continues to rise globally. Manufacturers provide tailored solutions to meet regional preferences and branding strategies.

-

What are the advantages of fabric storage boxes compared to plastic or wooden boxes?

>Fabric storage boxes are lightweight, foldable, and cost-effective, making them easier to transport and store compared to rigid plastic or wooden options. They reduce logistics costs for wholesalers and offer flexibility for end users. Fabric boxes also allow more design and branding possibilities, from eco-friendly linen options to colorful prints. While plastic and wooden boxes are stronger for heavy loads, fabric boxes remain the preferred choice for everyday home and commercial organization.

-

Can fabric storage boxes be waterproof or moisture-resistant?

>Yes. Certain fabrics, such as Oxford cloth or coated non-woven materials, can be made moisture-resistant to protect stored items from dampness. While fabric boxes are not fully waterproof like plastic containers, they provide sufficient resistance for general household use. For buyers targeting specific climates or applications, custom waterproof coatings or fabric upgrades can be offered. This flexibility ensures the boxes meet different environmental and market requirements.

-

What is the process of ordering custom fabric storage boxes?

>The process starts with inquiry and design discussion, followed by material and size selection. A sample is produced for confirmation, after which bulk production begins. Products undergo quality inspection before being packed and shipped. Throughout the process, OEM/ODM support ensures customization in fabrics, logos, and packaging. This structured approach gives wholesale buyers confidence in product quality, delivery time, and market readiness, making it easier to launch or expand their storage product lines.

Home

Home